Within this landscape, understanding the distinctions between mechanically and chemically recycled materials is crucial for navigating sustainable pathways. In this article, we explore the differences between these two methods, explaining their respective roles in sustainable resource management and the potential PCR materials hold for your packaging.

Understanding the differences between chemical and mechanical recycling

Mechanical recycling involves processing plastic waste into secondary raw materials without significantly changing the chemical structure of the material. This process relies on physical mechanisms such as sorting and shredding to transform used materials into raw materials for manufacturing. This method’s simplicity and cost-effectiveness make it suitable for processing homogeneous materials, especially PE and PP. However, the challenges with contaminated or mixed materials and aesthetics of the mechanically recycled materials limit its applicability in food packaging.

Unlike mechanical recycling, chemical recycling breaks down plastic to its molecular level. This process often utilises various chemical reactions, such as depolymerisation or pyrolysis, to transform complex plastics into simpler, more versatile building blocks. These blocks can then be used to produce new polymers or other products, enabling a true closed-loop recycling system where materials can be recycled indefinitely without loss of quality.

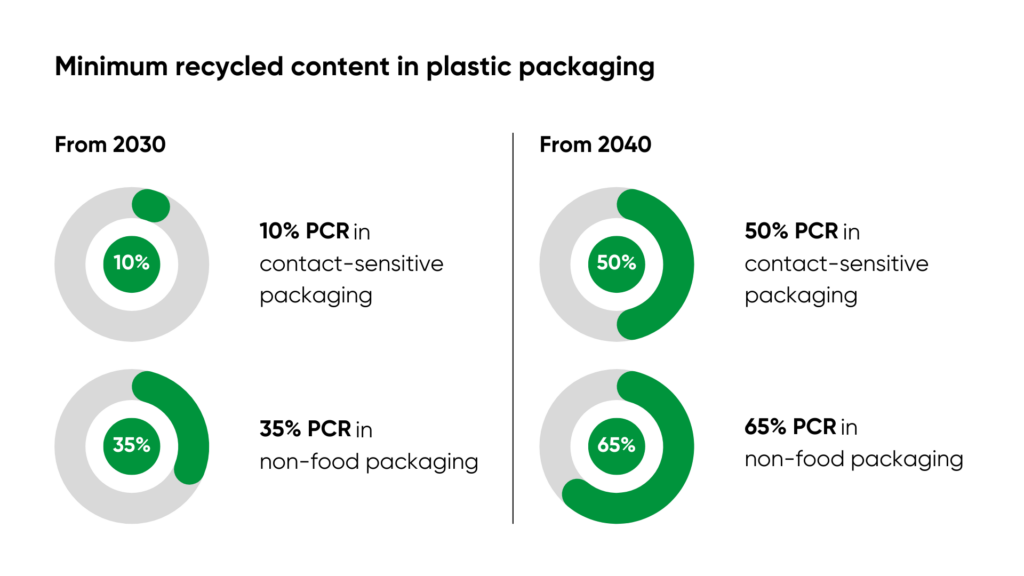

Having the qualities of brand-new or virgin resin, chemically recycled materials are suitable for demanding applications, such as food-contact and medical packaging, helping to achieve the proposed PCR targets of EU PPWR.

Traceability and transparency

To truly benefit your products with more sustainable packaging choices and create credibility among consumers, the use of recycled materials needs to be transparent and traceable. This is where mass balance approach comes to play, supporting the transition towards gradually replacing fossil materials with sustainable alternatives, especially in chemical recycling.

Under mass balance approach, certified alternative feedstock and fossil raw materials are physically mixed through complex manufacturing systems. Although materials cannot be physically separated, they are kept separate with verifiable bookkeeping. The main principle is to ensure that the total inputs align with the outputs. Estiko Packaging Solutions is ISCC PLUS certified, meaning that by using this approach, we can track and communicate the use of certified recycled content in our end products. In turn, our partners can transfer the certification into transparent and credible claims on their packaging. For food packaging, this is the best and easiest way to go, allowing brands to make meaningful claims, especially considering the newly adopted rules by the EU Parliament aimed at protecting consumers from greenwashing and misleading environmental claims on products.

Make the switch

While mechanical and chemical recycling methods offer distinct advantages and face unique challenges, they are not mutually exclusive. In fact, they complement each other, addressing different aspects of the recycling landscape. By harnessing the strengths of each approach and fostering collaboration and innovation, we can unlock the full potential of recycling and pave the way towards a more sustainable future.

Our team of experts can help you make the switch for more sustainable packaging solutions. Our recycle-ready packaging solutions for food and non-food applications are available with advanced certified recycled materials.

Eager to find out more? Dive into our case studies and contact our Sales team to see how using recycled content can help you meet your sustainability goals.